Changzhou Leap Machinery Co., Ltd.

Changzhou Leap Machinery’s predecessor

Changzhou Ruisheng Machienry is professional manufacturer for

monofilament extruding machine. Mr. Zexue Wu, The President, has

more than 20 years experience in the design and making of

monofilament machinery.

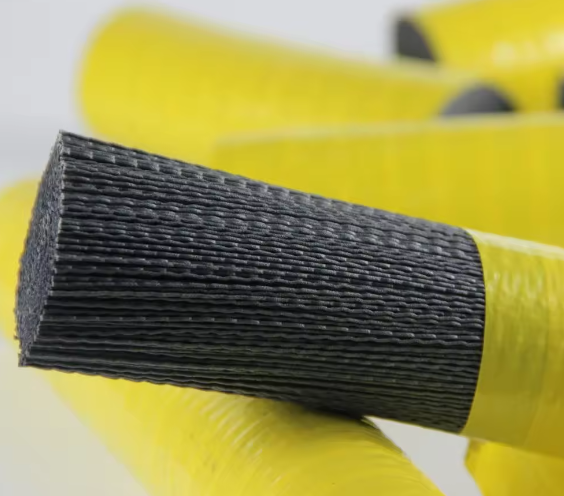

Our Main product is Nylon/Polyester/PP/PE Monofilament making

machine and design for whole plant projects.

Leap offers professional technology support and service to customer

based on it's abundant expertise in manufacturing, design, and

trading experience. Our working team has more than 50 high skilled

personnel, well experienced and responsible to promote the working

performance.

Leap insists on using the good material and parts to make the most

durable and high performance machines. Every machine must pass

strict and careful quality control system, and pass test running

before shipping out to the customer.

Our products have been successfully sold to more than thirty

countries.

We welcome new and old customers from

all walks of life to contact us for future business relationships

and mutual success!